SCREW CONVEYORS

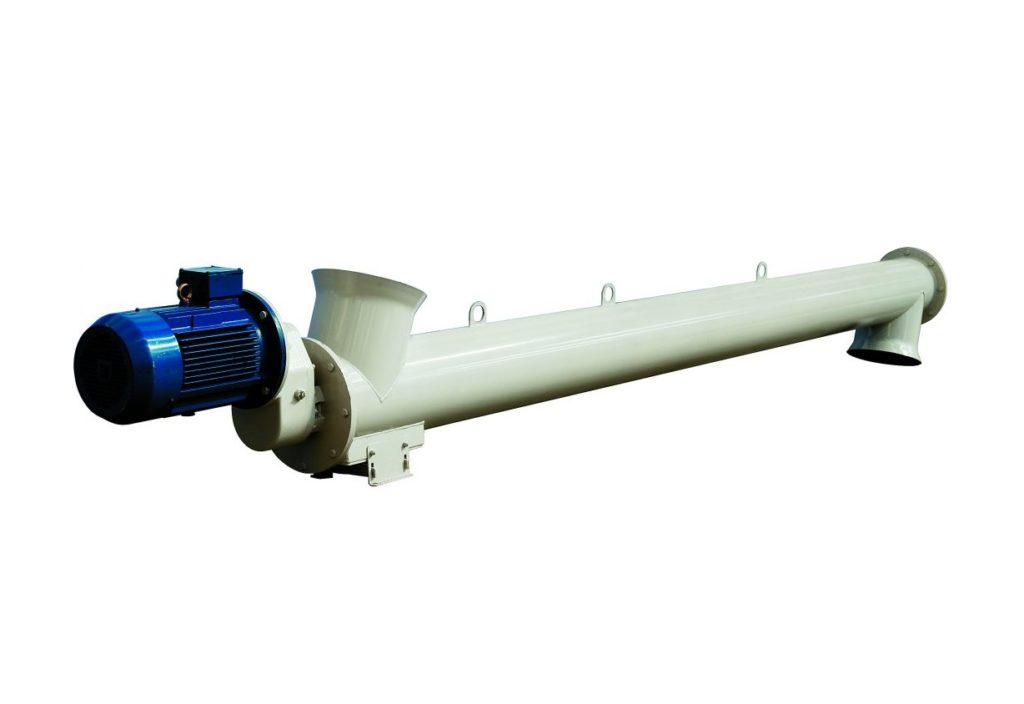

BASE® screw conveyors are made of painted carbon steel and are composed of an external cylindrical or bowl-shaped part and an internal spiral supported by intermediate hanger bearings, head supports and driven by gear motors. Screw conveyors are commonly made with a loading mouth and an unloading mouth of various types (flanged or cylindrical) positioned at the ends of the screw conveyor itself. At the customer’s request, they are made in various diameters and lengths.

BASE® screw conveyor is used for the transport of powders and granules of small-medium dimensions in general. Mainly used in concrete mixing plants, they guarantee a rapid and effective method for the extraction, transport and dosage of cement, ashes, calcium carbonate, sand, etc..

- Versatility of use

- Reliability over time

- Ease of installation

- Low maintenance costs

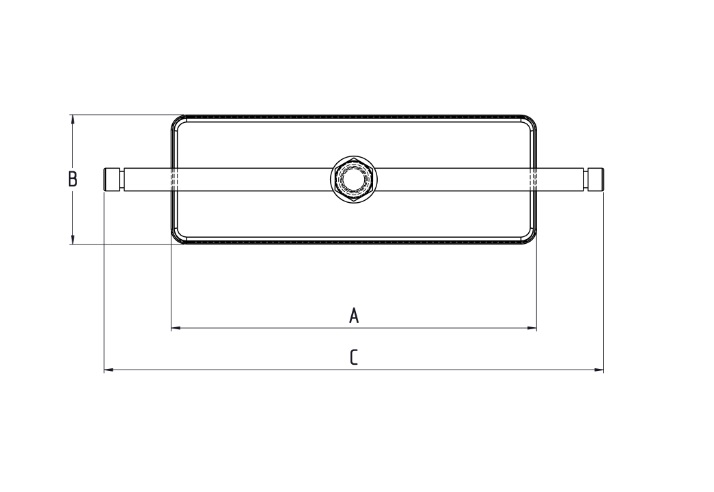

INSPECTION DOOR

Inspection doors of various sizes are made of galvanized steel, complete with rubber gasket and a clamping bracket.

They are mounted in the lower part of the screw conveyors in correspondence with the hanger bearings and the drive head, and are used to check the state of wear of the internal components and, if necessary, to carry out small repairs without having to disassemble the entire screw conveyor.

- Versatility of use

- Ease of installation

- Low maintenance costs

| Code | ∅ | A | B | C | Kg |

|---|---|---|---|---|---|

| BSXKA219 | 219 | 180 | 265 | 300 | 3.5 |

| BSXKA273 | 273 | 205 | 265 | 300 | 3.5 |

| BSXKA323 | 323 | 230 | 265 | 300 | 3.5 |