Safety valves, pinch valves, and level indicators, highly recommended safety devices to prevent damage to the silo and components of a concrete batching plant as well as to help decrease dusty material emissions to the atmosphere.

SAFETY VALVE

The BASE® safety valve is a mechanical overpressure control device that automatically intervenes when abnormal pressure conditions occur inside the silo. The valve body and closing discs (overpressure and underpressure) are made of painted steel with rubber gasket. The protection cap is made of stainless steel. The safety valve is mounted on the silo through a flanged connection, to be welded on the silo itself.

The safety valve is normally installed on sealed tanks for containing dusty materials. If the default setting remains within the desired limits, the three springs will keep the two discs hermetically closed. On the other hand, when there is an increase in pressure inside the silo, the overpressure disc lifts up to let the excess air out. When the pressure decreases, the underpressure disc opens allowing the external air to enter and re-establish the initial pressure inside the silo.

- Ease of installation

- Reduced maintenance costs

- Reliability over time

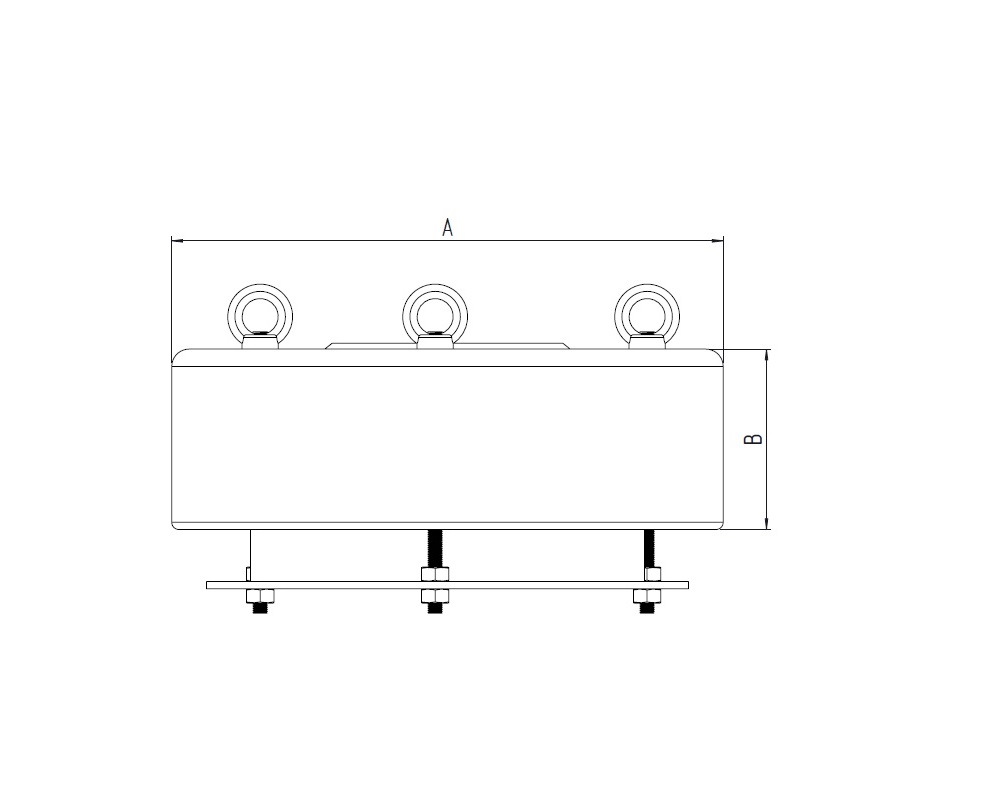

| Code | Description | Ø | A | B | Kg |

|---|---|---|---|---|---|

| BSVCP2731D | pressure relief valve | 273 | 382 | 125 | 6.5 |

| TECHNICAL FEATURES | |

|---|---|

| FACTORY SETTING | -50 mm H2O / 500 mm H2O |

| NEGATIVE OPERATING PRESSURE | -0.005 bar / +0.05 bar |

| AIR CAPACITY | up to 7.000 m³/h |

| BODY DIAMETER | 273 mm |

| PROTECTION CAP MATERIAL | stainless steel |

| VALVE BODY | painted carbon steel |

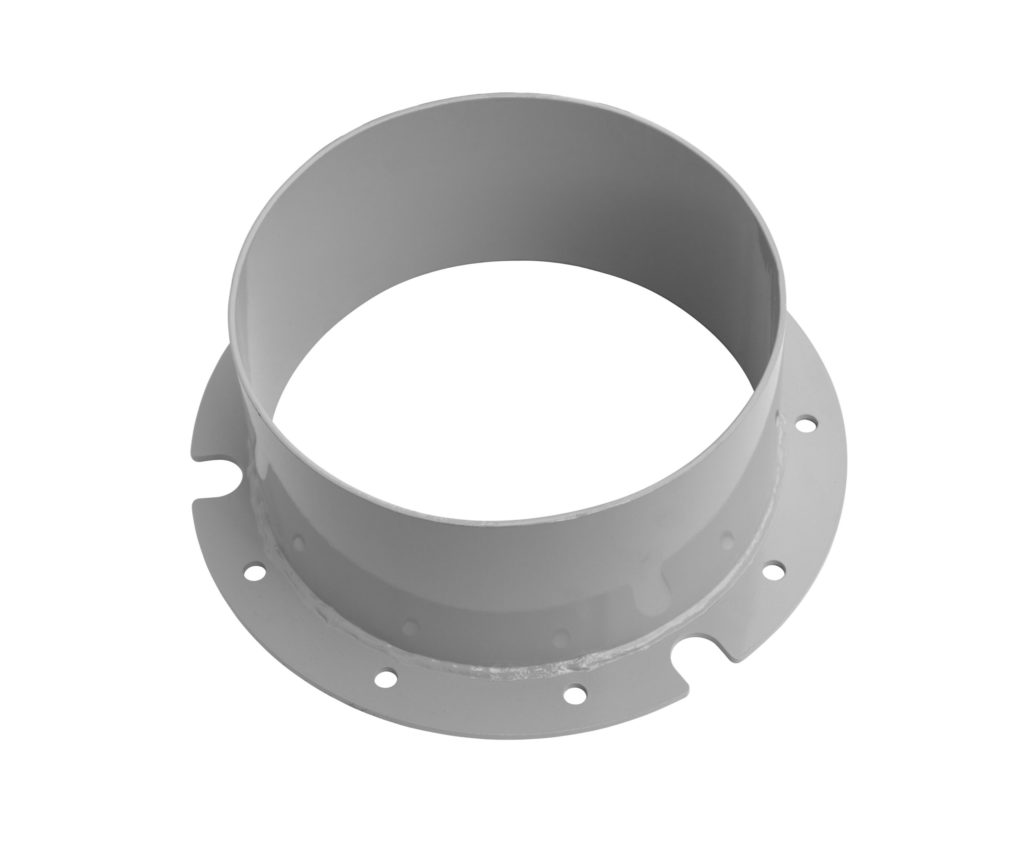

WELD-ON FLANGE

The safety valve is mounted on the silo using a flanged fitting, to be welded on the silo itself.

| Code | Description |

|---|---|

| BSRV2731D | sealing flange |

PINCH VALVE

The pinch valve is composed of a die-cast aluminium body flanged at both ends and shaped in such a way as to exert maximum air pressure on the anti-wear rubber sleeve located inside the valve itself.

The DN100 sleeve valve is normally used in safety systems for pneumatic loading of cement and powders into storage silos. It allows the pneumatic closing of the product flow when the working pressure of the control system exceeds the allowed threshold.

- Ease of installation

- Compact size product

- Low maintenance costs

| Code | Description |

|---|---|

| BSVM100AA0 | flanged pinch valve DN100mm |

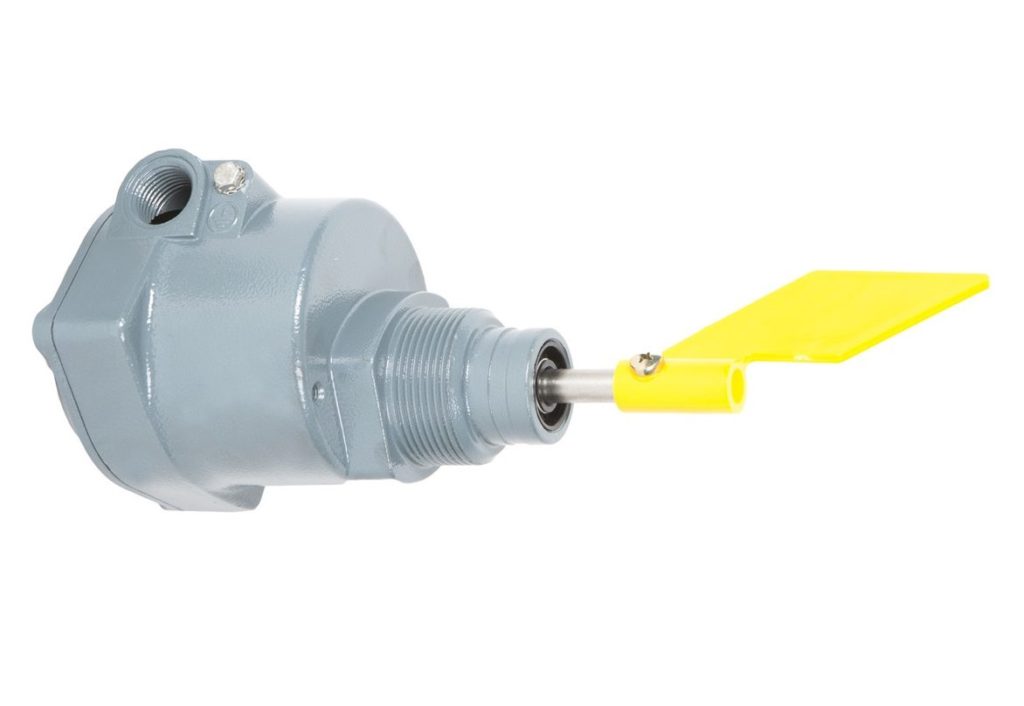

LEVEL INDICATOR

BASE® rotating paddle level indicators made of die-cast aluminium, watertight, for silos and powder containers in general. They have a 1″1/2 gas connection thread and a plastic paddle. On request, it is possible to have indicators with different types of fixing, construction standards for high temperatures, liquids, etc. Together with the level indicator we usually supply the adapter which allows to install our indicator on old generation sleeves with 2″1/2 thread.

The level indicator is usually used to detect the minimum and maximum level of the product contained inside the silo of the batching plant. In case of use as a maximum indicator, the alarm signal will be sent by the indicator only when the paddle is completely immersed in the product and therefore can no longer rotate. In the case of use as a minimum indicator, by modifying the electrical connections, the alarm signal will be sent when the paddle is freed from the material and can start to rotate.

- Ease of installation

- Low maintenance costs

- Compact product dimensions

- Versatility of use

| Code | Description | Volt |

|---|---|---|

| BS003.102 | level indicator 50/60 Hz | 24/48 |

| BS003.112 | level indicator 50/60 Hz | 110/200 |

ADAPTER

| Code | Description |

|---|---|

| BS003.100 | adapter from 2"1/2 a 1"1/2 |